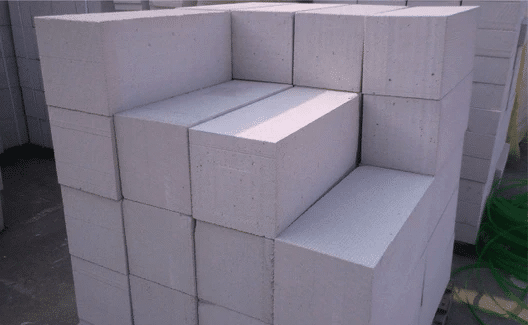

AAC Blocks

AAC blocks are highly durable and strong. They have high compressive strength and can resist heavy loads, making them suitable for use in both load-bearing and non-load-bearing walls.

| Dimensions | 600mm x 200mm x 50 mm(2″)

600mm x 200mm x 75 mm(3″) 600mm x 200mm x 100 mm(4″) 600mm x 200mm x 150 mm(6″) 600mm x 200mm x 200 mm(8″) 600mm x 200mm x 230 mm(9″) 600mm x 200mm x 250 mm(10″) 600mm x 200mm x 300 mm(12″) |

| Thickness | 50mm – 300mm |

| Compressive Strength | 4N / Sq.mm |

| Density | 550 to 650 kg/m3 |

| Thermal Conductivity | 0.12W/m-k |

| Sound Reduction (db) | 35 to 60 (db) |

| Fire Resistance | 1600 degree / 6 hrs for 200MM Thickness |

| Precision in Size | Variation 2MM (+/-) |

Gallery

Fast returns on investment due to speedy construction

Uniform quality due to mass production

Saving in installation and recurring cost of air conditioning units

No curing or plastering required

Directions to Use

Always clean the surface before application to remove any loose particles or laitance.

Ensure that the surface is solid (hard and rigid) for the given applications and free from voids, holes and cracks.

Pre-wetting of blocks.

Ensure surface is well saturated before application.

Mix 3 Part BOND to 1 part water (by volume) and mix to smooth, workable stiff paste.

Always add the powder to water.

Allow the mix to stand for 2-3 min for the paste to mature.

Do not add water to the already mixed mortar to extend the pot life.

Put well-mixed BOND on the block with the help of trowel, spread mortar uniformly on the unit for a 3mm bed thickness.

Firmly place the block with slight shear to ensure proper transfer and bonding.

BOND to be applied on the block and on column and beam for good bonding at the joints.